Getting into the workforce and what I learned along the way.

If there was a template for a below average, confused student, I’d fit the description perfectly. Consistent low grades, not a lot of friends, and no real passion for anything really.

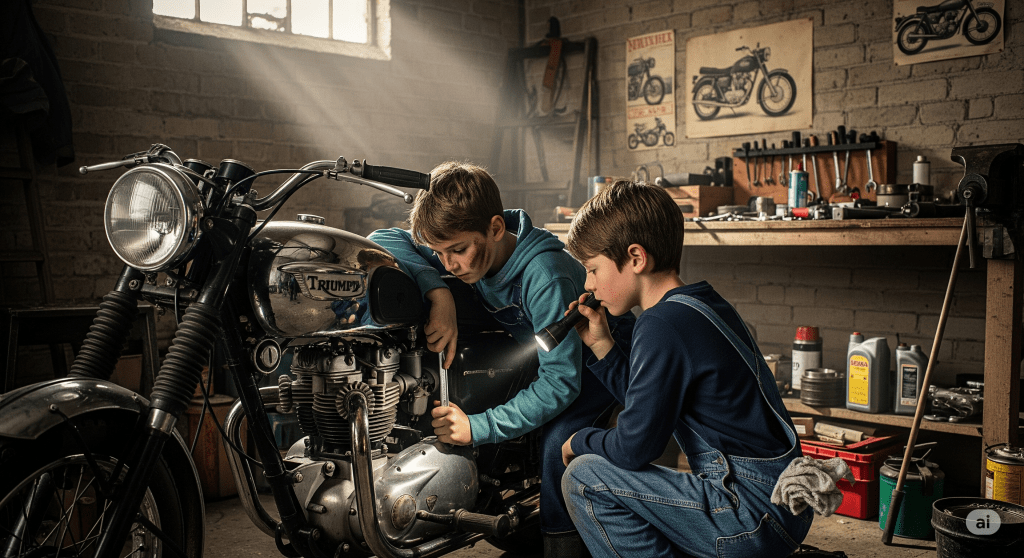

The only people that kept me going were perhaps Rocky Balboa and Tony Stark, both having an interest on cruiser bikes. In the lore, Tony supposedly built his first bike at 10 years of age, so I believed that’s where real engineering started.

But first, a little backstory.

Fresh out of College

This was early 2010s, and the only jobs available were through campus recruitment interviews. I didn’t crack any.

Naturally, our story begins six months of unemployment later.

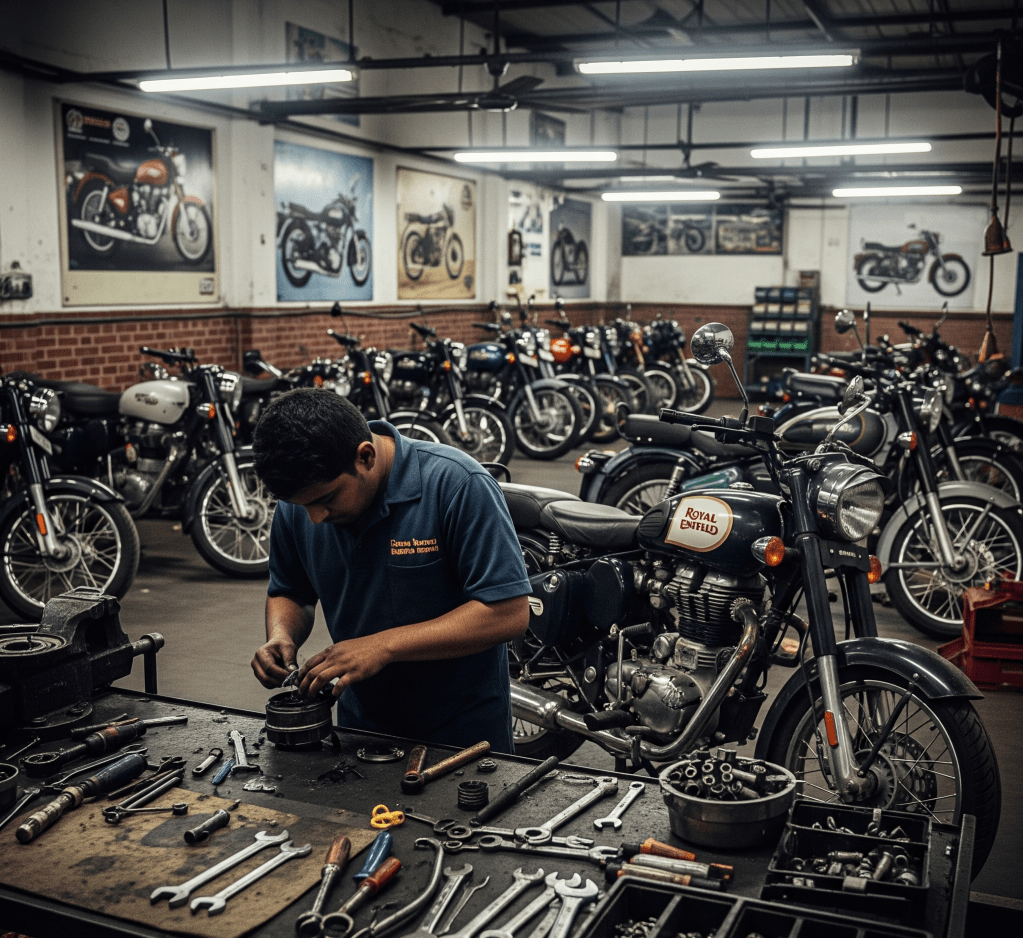

At the time, I used to vist my friend’s home almost every day. They had a very old Royal Enfield Bullet that his dad kept in pristine riding condition. It was fun to watch his dad work on it frequently, changing and adjusting some or the other part of the machine.

It was the same time my brother brought me a book on bike history – ‘Hot Bikes’ by Hugo Wilson. I loved the cover of the book – an old Indian Chieftain in fiery red with frills on the saddle.

I knew I was hooked on bikes by then, revering every old or curious machine that caught my eye.

I too had a Royal Enfield Thunderbird we bought a year ago. My old neighbor Varsh and I used to go on little drives around the city – me on my brand new bike and him on his ’92 model bullet single seater.

Thanks to my joblessness, taking the bike to workshops for checks became my latest hobby/duty. Watching mechanics adjusting clutch and brakes, while others working on other engines gave me a glimpse of how well designed these simple machines were.

I wanted to fix bikes, but four reasons led me to pursue fixing bikes for a living.

- Pride. I was a mechanical engineer, so I am supposed to work on machines.

- Love. I saw how people maintained their Royal Enfields with utmost affection.

- Curiosity. I wanted to know what happened inside these machines.

- Poverty.

Small talk sparks an opportunity

I was still miles away from a job.

Since I had a lot of time to kill, I was assigned to take the bike out for service and wash it occasionally. On one such visit, I met a service advisor after the bike got fixed, and we got into a talk describing how awesome the new Unit Construction Engine or UCE was.

The talk apparently took hours to finish that he asked if I wanted to work there. I mentioned I had never used a spanner before, but he was kind enough to set up an interview with his manager.

My first interview happened inside a service center.

Amidst the addicting smell of engine oil and the deafening noise of revving engines, I was eager to explain the history of Royal Enfield engines to the supervisor and the boss of the showroom.

After a couple of hours of discussion, I got the job. A fat sum of Rs.3000 was agreed. I was just happy that I was getting paid in addition to working on bikes.

Life at a worshop

I distinctly remember the look of rejection from my dad when he got to know of my new job. Surely that wasn’t something a mechanical engineering degree is supposed to earn. So from day one, it was all on me to make it a happy experience.

Days began as early as 5.30. Boarding a bus at 7 to reach a common bus station and another bus to the dealership took more than an hour of commute.

Also, there weren’t any buses that passed through the dealership, so there was usally a brisk walk of a kilometer to reach the place. I didn’t mind any of it.

Back then, mechanics and service advisors were supposed to report early, since customers dropped their vehicles on their way to work. Experienced mechanics came only by nine, but I was always there to open the workshop at 8.30 am or well before that.

From day one, I was assigned a mechanic to get me up to speed with the basics.

- Air filter cleaning/change

- Oil filter cleaning/change

- Chain and clutch adjustments

- Fresh oil pumped from the drum

- Bring spanners and tools to my mechanic

- Push the bike for washing

- Ensure the bike’s owner sees the fully serviced shiny motorcycle

I was a diligent student, for I learned all the basics with fairly limited number of blunders. All this effort was to get promoted to be the apprentice of the chief mechanic, a rusty fifty-year old who had no interest in following the rules at the service centre.

Work was quite extensive; occasionally delivering fixed motorcycles to the client’s doorsteps to last minute service requests that forced me to stay back a bit more.

Mixed Satisfaction

I remember one time when I was all worked up at the centre and had to catch a bus quite late. Since it was post 7.00pm, there weren’t many buses that went on my route, so I walked to the bus stand a couple kilometers away.

The A/C low floor bus that went straight to my home came by and I hopped in. This bus route had a specialty – it went through the IT park to collect tired tech people to their homes.

As soon as they came in, the bus got fairly crammed with well-dressed, perfumed gentlemen and ladies.

I could see exhaustion on theiir faces. It was fairly late, and they had to return to their desks the next day, so their expressions were predictable. I was right in the middle of them, smelling like engine grease and burned oil, revelling in my musty work clothes.

My reflection on the illuminated window smiled ear to ear from a good day’s work. Staring at my blackened callus worn hands for the longest time, it was a day I remember to this day.

I still didn’t have the money to afford the luxury of air conditioned bus transportation, but I thoroughly enjoyed this one. Renewing a passion for motorcycles, I began to think of ways to contributing more at the workshop.

2 ideas that kept me up

Bike with regenerative suspension

The time I got the job coincided with Indian Motorcycle’s second coming. Their proprietary new engine and the revitalized design I once saw on the cover of Hot Bikes almost felt magical.

At the time, I had an idea to device a regenerative suspension, that which we do with regenerative braking, just more optimized for suspension. It was a childish idea as I think of it years later.

Through a linkage, I wanted to create a suspension system that perfectly damped every bump and undulation on the road.

There were a few schematics I drew up back then, but now I realize I did drew up a system that could’ve shot the rider up in the air. But it was thoroughly exciting.

Tech discussion on motorcycle parts

Since I wasn’t considered a full-fledged mechanic, I had a lot of time to fool around the workshop. One thing that came forth clearly was this: us mechanics preferred working than explaining customers what went wrong.

Service advisors were the exact opposite. Their role was to convince that they knew exactly what was wrong with the bike and suggest solutions that appeased the customer. This was a problem as there was this idea being prevalent that advisors were more knowledgable.

It also followed that mechanics were given promotion as service advisors if they wanted to. Less sweaty work, more talk – looked like an exciting prospect. But the real problem was mechanics not being responsive to customers.

Our service centre even had a waiting lounge from where people could see us work. So if a customer wished to talk, it would’ve made a huge difference if at least some of the mechanics could speak to them. This never happend.

It was the same time I came across the shop manual that hadn’t seen the light of day in a very long time. When asked if our mechanics know about the book, our manager was happy to lend me the book and see if I could introduce it to the shop.

And that’s how I ended up taking a short class on how an engine cutoff valve worked. I’ve long forgotten the name of the device, nor where it’s present in the engine, but it was good enough to be taken seriously and we began having such discussions every week from then on.

We began to say the actual name of the parts than just calling them lock nuts or pipes. So there was definitely progress.

A short-lived bike-fixing career

The threat of no lunch money soon kicked in as I couldn’t do much with my salary. Sure, it did cover my bus fare and the occasional cheap meal from a nearby lunchplace. I still loved the work, but it was getting harder not to rely on funds from home to go to work.

After a really long back and forth with the team, I decided it was time to leave. I never thought I was leaving behind my bike fixing career, but time washed that passion away too.

There was a day towards the end of my tenure when we had a bike expo near a beach and a north Indian family came to check out our bikes. They had questions, but none could answer them. Eager to help, I was quite happy explaining whatever little I knew and create an interest in the bike.

Don’t know if they ever bought one, but they were happy.

I still get excited seeing bikes at workshops. I was part of the scene years ago, but I also feel for the people who work there, often underappreciated and underpaid. Tinkering away in crammed dark spaces with spanners and screw drivers around, these folks are my go to people for small talk.

Next time you bring your bike to a workshop, remember our little story.

Leave a comment